Electrostatic discharge is a spark or a sparkover resulting from a large potential difference in an electrically insulating material, which causes a very short high electrical current pulse. A cause of the potential difference is usually a loading by triboelectricity.

• Lightning

• Discharge by touching a car door

• Crackling from the many small discharges when removing a sweater

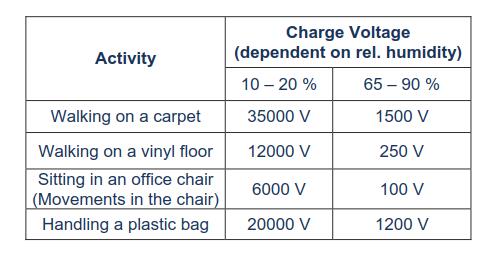

Many normal everyday activities cause very high voltages which are generated in our bodies. A human can feel electrostatic discharges from 3000V and higher. Semiconductor devices, including LED and LED driver, can easily be damaged by ESDs with a few volts.

LED can be damaged by ESD so badly that they fail totally. This means, that they emit neither light nor are electrically conductive. If the LED is damaged, but still electrically conductive, it is considered disturbance.

An LED, which is completely failed by ESD, does not only remain completely dark, but is also no longer electrically conductive any longer. Therefore also any further LED in series connection do not light, even if they are undamaged. This is immediately visible after the damage.

In contrast to total failure, LED can be damaged in a way that initially still light, however rapidly become dim. Since the damaged components remain electrically conductive, the remaining module continues to light normally.

• Damaged LED can initially light

• Becomes dim quickly

LED can be damaged by ESD so badly that they fail totally. This means, that they emit neither light nor are electrically conductive. If the LED is damaged, but still electrically conductive, it is considered disturbance.

Left Pictogramm indicates that ESD preventive measures have to be taken. Objects and work areas can be marked.

• Grounding with help of a special reel

• Conductive footwear

• Heel bands should be worn on both feet, in order to ensure a constant contact to the ground

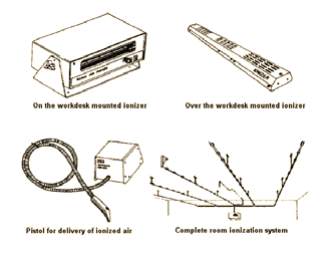

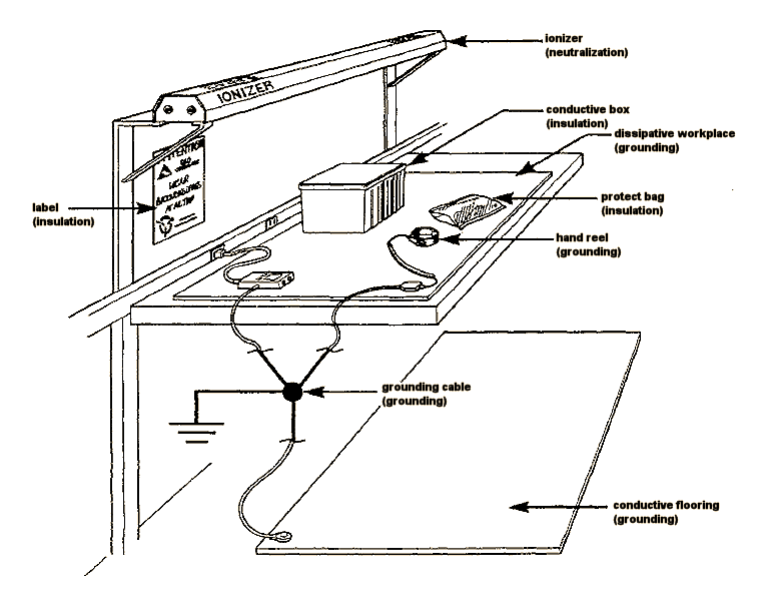

If an isolator is statically loaded, ESD damage can be caused by contact. In order to reduce this risk, an ionizer can be used, which produces billions of charged particles and thus neutralizes the static loading of the isolator.

• Neutralisation replaces neither grounding nor prevention!

Example of a staticsafe workplace

a) In general

• Never enter a ESD protected area, without making the appropriate safety precautions.

- at an ESD protected work desk there should be no

unnecessary articles e.g. coffee cups or other

insulators

- soldering irons, screwdrivers and other tools

should be ESD certified, recognizable from adjoining

symbol

- test grounding devices daily

b) for LED Systems

• For handling the modules also wear grounding cotton gloves.

• It also applies for the transfer of modules from one person to another one

• Avoid touching the metallic contacts.

• For ESD safe laquering of the modules we recommend the use of spray lacquer. If you should apply the lacquer with a brush (not recommended), do not use brushes with plastic fibers.

• The modules should be kept separated during storage and transport in such a way that they cannot touch each other. Also avoid components or modules coming into contact with clothes, hair or other insulators (e.g. carpet).

• The consideration of these measures reduces the occurrence of ESD damages, but can not exclude them completely.